Designed to be integrated into line with built-in automatic reject and available in 300, 500 and 600 mm belt width models, the X5 Pack is perfect for a variety of unpackaged and packaged products.

Offering good detection levels on a wide range of contaminants including all metal, bone, glass, dense plastics, foil trays or even metalized film.

The reliable heavy duty conveyor components, built for 24/7 operation with pass key protective Set-up comes integrated with a Windows 10 PC with Modem, Ethernet and front access USB port.

Versatile detection with LOMA’s AAT technology

AAT technology allows the X-Ray Diode setting to be changed depending on the product you are inspecting, offering the very best detection levels across the board. Using a 0.4mm setting for very small metal contaminants and 0.8mm and 1.6mm to find softer contaminants such as bone, ceramic and glass.

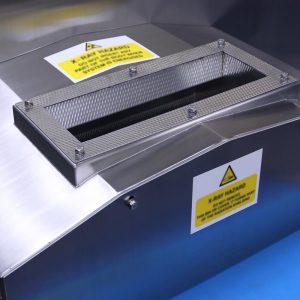

Fully enclosed CCP solution with integrated reject station

All in one system with optional retail compliance options, the X5 Pack offers complete control and removes risks. Reject options include air blast and pusher.

Get inspecting fast with LOMA’s product learn wizard

A set-up wizard automatically optimises the X5 Pack for each product type & allows you to learn or allows you to learn or switch to new products within minutes.

Ideal for these products

- Convenience Food

- Dairy and Egg Products

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

Additional Features

- Check product integrity including counting and missing items

- Manufactured with LOMA’s “Designed to Survive” philosophy

- Lead free construction

Specifications

Material of Construction: 304 Brushed stainless steel

System Length: 2000mm

Line Height Option: 700 – 1100mm (+/- 50 adjustment)

X-Ray Output: 150W (60kV 2.5 mA)

IP Rating: IP66

Belt Width: 300/500/600mm

Belt Type: PU Anti-static

Weight on Belt: Up to 25kg

Speed Range: 20 – 80 m/min

Supply Voltages: 85 to 265 V, single phase 50/60Hz, neutral & amp;Earth

Cooling: Vortex or AC Air Conditioning

Operating Environment (Standard): 2 to 10oC with cabinet warm up, 10 to 25oC with Vortex

Operating Environment (Optional): 25oC to 35oC AC Air conditioning (Cabinet reduced to NEMA 4x with AC Option)

X-Ray Safety: Leakage less than 1 μSv/h

Detection Algorithms: 15 Multilayers Algorithms combined in any combinations

Reporting: Event, Batch, Shift, PVS

Data Retrieval: Via USB, Ethernet, Tracs

Reviews

There are no reviews yet.